Midwest Roots

These 28 fundamentals bring our values to life and make our mission real.

Online ordering is currently not available. Please email mtsales@midwest-trading.com or call 630-365-1990 to place your order.

These 28 fundamentals bring our values to life and make our mission real.

Our Mission is to meet the expectations of our customers in the horticultural and related fields with quality non-plant products and services while providing the owners and employees an opportunity to advance their business and personal goals through the company in an enjoyable and fulfilling way.

Relationships

People

Teamwork

Improvement

Products & Services

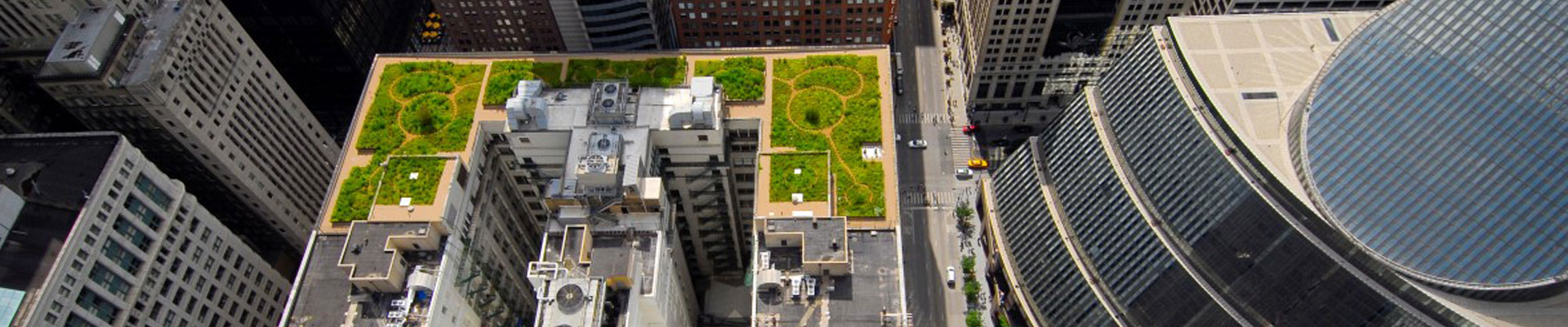

Sustainability

View Our Values

Phone: (630) 365-1990

Fax: (630) 365-3818